Laser Welding Machines: The Real Upgrade Your Workshop Didn’t Know It Needed

The Evolution of Welding Technology

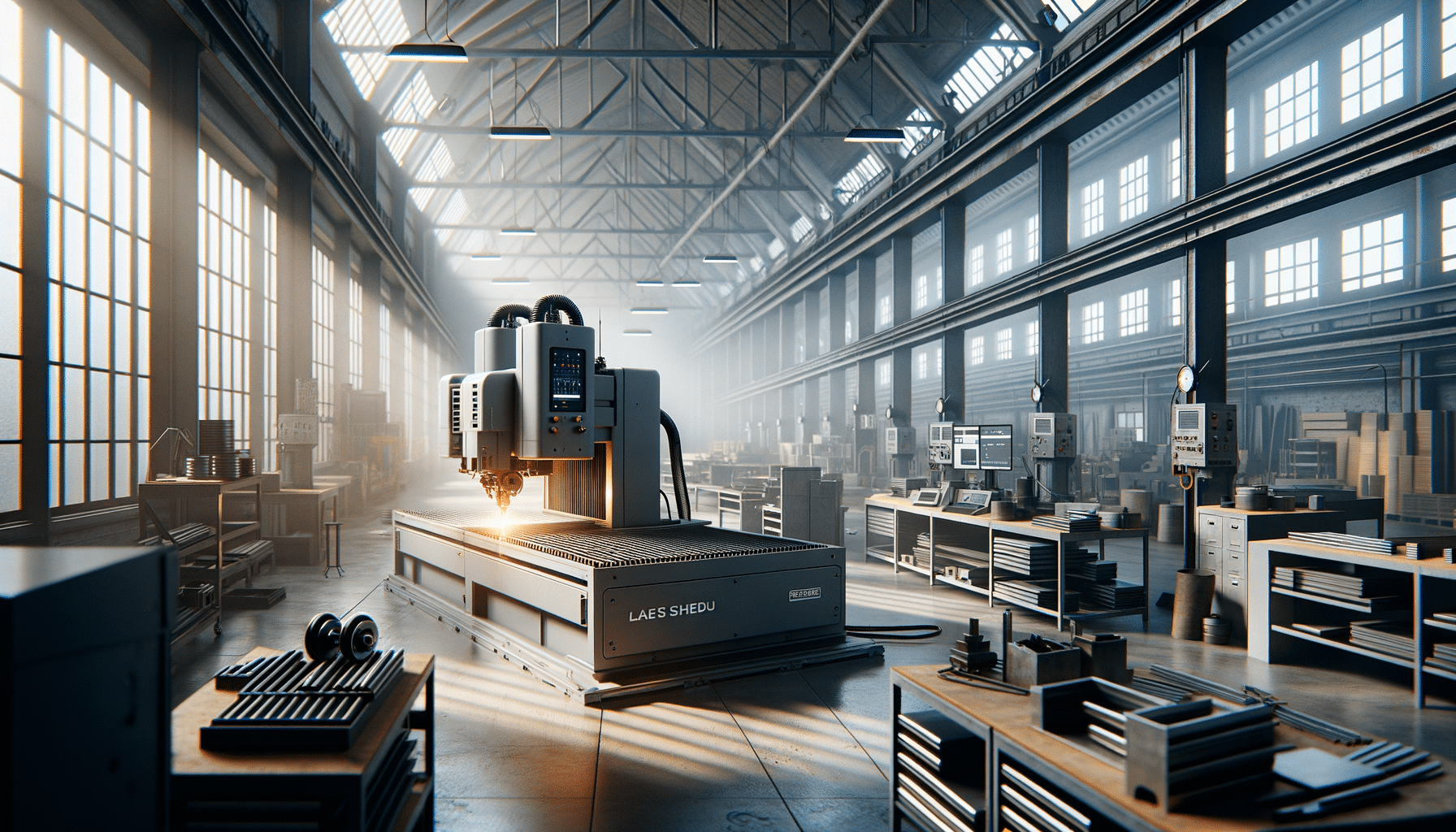

Welding has come a long way since its inception, evolving from traditional techniques to the cutting-edge technology we see today. Among these advancements, laser welding machines stand out as a remarkable innovation that has transformed the landscape of metal fabrication. Initially perceived as high-end equipment reserved for large-scale industrial applications, these machines have gradually made their way into smaller workshops. This shift is largely due to their ability to deliver precise and clean welds while significantly reducing the time and effort traditionally associated with welding processes.

Laser welding machines utilize a highly concentrated beam of light to join materials, offering unparalleled precision and control. This method not only enhances the quality of the weld but also minimizes the risk of distortion and defects. As industries increasingly demand high-quality outputs, the adoption of laser welding machines has become a strategic move for businesses aiming to stay competitive.

Today, laser welding is not confined to large factories; it is a viable option for small workshops and custom fabricators. The accessibility of this technology has empowered smaller operations to deliver exceptional results, previously thought to be achievable only by larger enterprises. As the technology continues to evolve, laser welding machines are expected to become even more integral to manufacturing processes across various industries.

Key Advantages of Laser Welding Machines

The rise in popularity of laser welding machines can be attributed to several key advantages they offer over traditional welding methods. One of the most significant benefits is their ability to produce cleaner welds. The precision of the laser beam allows for minimal heat input, reducing the risk of warping and other thermal distortions. This results in a cleaner, more aesthetically pleasing finish, which is particularly important in industries where the visual appearance of the weld is critical.

Another advantage is the speed of the welding process. Laser welding machines are capable of joining materials at a much faster rate than traditional methods, thereby increasing productivity and efficiency. This is especially beneficial for businesses that require high-volume production without compromising on quality.

Furthermore, laser welding machines offer greater flexibility in terms of the materials they can work with. They are capable of welding a wide range of metals, including those that are difficult to weld using conventional methods. This versatility makes them an invaluable tool for businesses that work with diverse materials and need to adapt quickly to different project requirements.

In addition to these benefits, laser welding machines are known for their reliability and consistency. The automated nature of the process ensures that each weld is performed with the same level of precision, reducing the likelihood of errors and rework. This reliability translates into cost savings for businesses, as it minimizes material wastage and reduces the need for extensive post-weld treatments.

Applications Across Industries

The versatility of laser welding machines has led to their widespread adoption across various industries. In the automotive sector, for instance, they are used to join components with high strength and precision, ensuring the safety and durability of vehicles. The aerospace industry also relies on laser welding for its ability to produce lightweight yet strong structures, which are essential for aircraft performance.

In the medical field, laser welding machines are utilized to manufacture medical devices and instruments that require precise and clean welds. The technology is particularly valuable for producing components that come into contact with the human body, where contamination must be avoided at all costs.

Electronics manufacturing is another area where laser welding machines shine. The precision and control offered by laser technology are crucial for producing intricate electronic components with minimal risk of damage. This is especially important in the production of consumer electronics, where miniaturization and high performance are key considerations.

Additionally, the jewelry industry has embraced laser welding for its ability to repair and create delicate pieces without damaging the surrounding material. The precision of laser welding allows jewelers to work with fine details, enhancing the quality and craftsmanship of their creations.

Cost Considerations and Accessibility

One of the initial barriers to the widespread adoption of laser welding machines was their cost. However, as technology has advanced and become more widely available, the price of these machines has decreased, making them more accessible to smaller businesses and workshops. This democratization of technology has opened up new opportunities for businesses that previously could not afford such investments.

When considering the cost of a laser welding machine, it is important to factor in not only the initial purchase price but also the long-term savings it can provide. The efficiency and precision of laser welding often result in reduced labor costs and less material wastage, which can offset the initial investment over time.

Moreover, the maintenance requirements for laser welding machines are typically lower than those for traditional welding equipment. The durability and reliability of these machines mean that they require less frequent servicing, further contributing to cost savings in the long run.

For businesses looking to invest in laser welding technology, it is crucial to evaluate their specific needs and choose a machine that aligns with their production goals. By doing so, they can maximize the benefits of laser welding and achieve a higher return on investment.

The Future of Laser Welding Technology

As laser welding technology continues to evolve, its future looks promising with several exciting developments on the horizon. One area of advancement is the integration of artificial intelligence and machine learning into laser welding systems. These technologies have the potential to enhance the precision and efficiency of the welding process even further, allowing for real-time adjustments and optimization.

Another promising development is the expansion of laser welding applications in additive manufacturing, also known as 3D printing. By combining these technologies, manufacturers can create complex structures with intricate designs that were previously impossible to achieve with traditional methods.

Additionally, advancements in laser technology are paving the way for more environmentally friendly welding processes. As industries strive to reduce their carbon footprint, laser welding offers a cleaner and more sustainable alternative to conventional welding methods, which often involve harmful emissions and waste.

Overall, the future of laser welding technology is bright, with continuous innovations that promise to enhance its capabilities and broaden its applications across various industries. Businesses that embrace these advancements will likely gain a competitive edge, positioning themselves as leaders in their respective fields.